Call Us

+91 98665 70999

About HSPPEB

Crafting Steel Solutions with Innovation and Expertise.

HSPPEB specializes in providing high-quality, cost-effective solutions for Pre-Engineered Steel Buildings. With a proven track record of innovation and customer satisfaction, we bring decades of expertise to every project, ensuring tailored solutions that meet diverse industry needs.

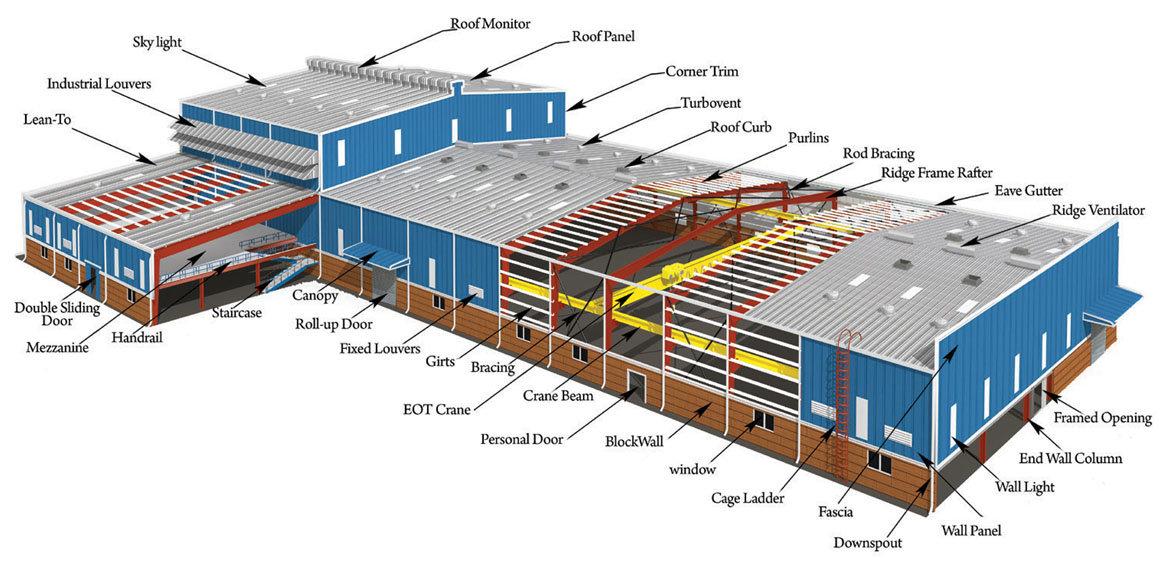

Pre-Engineered Building

Shaping Tomorrow with Precision-Engineered Steel Solutions.

Pre-Engineered Buildings (PEB) are the future of construction, offering unmatched flexibility in design and rapid installation. Delivered as a complete package, PEB structures eliminate the need for on-site fabrication, ensuring precision, efficiency, and quality.

Why Choose Us

Your Trusted Partner for Precision and Performance.

At HSPPEB, we combine cutting-edge technology with decades of expertise to deliver steel solutions that stand the test of time. From concept to completion, our team ensures precision, quality, and customer satisfaction. Whether it’s a small-scale structure or a complex industrial facility, we bring a commitment to excellence to every project.

Advantages

Building Smarter, Stronger, and Sustainable Solutions.

HSPPEB structures offer more than just durability; they are a smart investment for businesses seeking efficiency and sustainability. With our innovative approach to construction, we provide solutions that minimize costs, reduce timelines, and maximize value.

- Single-source responsibility for seamless delivery

- Faster project turnaround with precision

- Flexible and expandable structural designs

- Sustainable and eco-friendly steel structures

- Minimal maintenance required for longevity

- Expertly engineered for strength and reliability

Frequently Asked Questions

Understanding the unique benefits and applications of Pre-Engineered Buildings is essential when planning your construction project. Below, we’ve compiled answers to some of the most common questions to help you learn more about PEB solutions and how they can cater to your specific needs.

1. What is PEB?

Pre-Engineered Buildings are steel structures designed and manufactured at a factory, then assembled on-site for rapid and efficient construction.

2. What industries can benefit from PEB structures?

PEB structures are versatile and used in industries such as warehousing, manufacturing, retail, healthcare, agriculture, and more.

3. How durable are PEB structures?

PEB structures are made from high-strength steel and are designed to withstand extreme weather, seismic activity, and heavy loads.

4. Are PEB structures environmentally friendly?

Yes, PEB solutions use recyclable steel and generate less construction waste, making them a sustainable option.

5. Can PEB buildings be customized?

Absolutely. PEB structures are tailored to meet the specific dimensions, functions, and design requirements of your project.

6. How long does it take to construct a PEB structure?

Construction timelines are significantly shorter than traditional methods, with many projects completed within weeks.

7. What maintenance is required for PEB buildings?

PEB structures require minimal maintenance, mainly periodic checks for corrosion and ensuring proper drainage systems.

8. Are PEB buildings suitable for multi-story construction?

Yes, PEB systems can be designed for multi-story applications, making them ideal for commercial and residential buildings.

9. What are the cost advantages of using PEBs?

PEBs reduce labor and material costs due to factory manufacturing and faster installation times, making them a cost-effective solution.

10. Can PEB structures be expanded in the future?

Yes, PEB designs are modular, allowing for easy expansion to accommodate growing business needs.

Ready to bring your vision to life? Partner with HSPPEB for innovative, efficient, and high-quality steel solutions. Contact us today to discuss your project needs!

+91 98665 70999

Trusted by Our Esteemed Clients